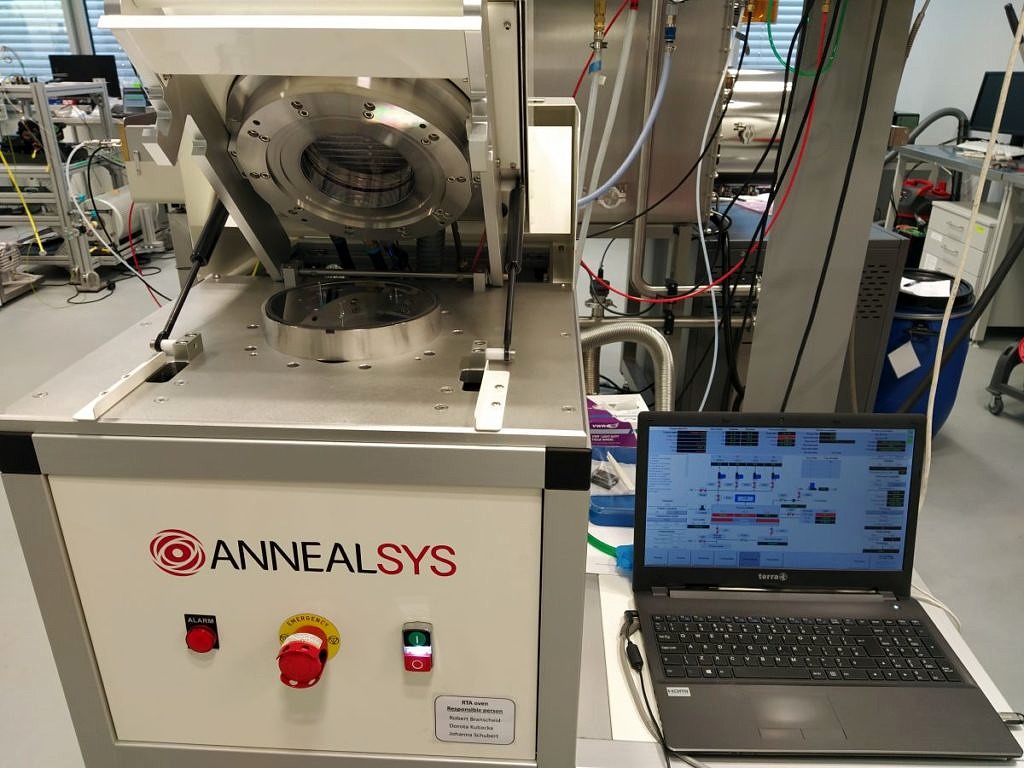

Rapid thermal annealing furnace

Rapid Thermal Annealing (RTA) furnace AS-One 100 from Annealsys is an advanced system commonly used in a semiconductor manufacturing process, designed for short-duration and high-temperature annealing. The heating is realized by tubular halogen lamps located behind a quartz window, which allows precision temperature control. RTA enables fast and precise heating and cooling ramp control up to 200 ⁰C/s. Moreover, different gas mixtures (argon, oxygen, hydrogen and nitrogen) and a wide range of pressure (from atmospheric to high vacuum) can be applied. Substrate material with 10 cm diameter is placed on three quartz pins, which reduces the thermal transfer. We use Si or Si3N4 wafer for bulk samples or silicon carbide coated graphite susceptor with a lid for thin and smaller samples. The temperature measurement is realized by pyrometer below the substrate. Therefore, it is guaranteed to receive the signal from the wafer, instead of the lamps. The AS-One system has a stainless steel cold wall process chamber for better process reproducibility and higher cooling rates. RTA is a powerful tool with various applications, which already extend beyond semiconductors, like solar cell fabrication or investigation of early stages of high-temperature oxidation. We successfully use it for the dewetting experiments (AuNi system) and oxidation studies of Ni- and Co-based superalloys.

Key specifications:

- Temperature range: RT to 1250°C

- Heating rate up to 200°C/s

- Cooling rate up to 200°C/s

- Gas mixing capability with mass flow controllers (O2, N2, Ar, H2)

- Vacuum range: Atmosphere to 10-6 Torr

- Full PC control with Windows compatible software

- Possibility of creating complex and multi-step heating recipes