Two paper contributions by IMN/CENEM researchers to Proceedings of Superalloys 2020

Two research papers from the high-temperature group have been published recently in the Proceedings of Superalloys 2020. The principal goal of the symposium is to highlight new initiatives and future growth opportunities for superalloys that are used in gas turbine engines and related applications. In one of the publication, authored by Dorota Kubacka and coworkers presents the potential of a rapid thermal annealing procedure to study and explain the differences in oxidation behavior of Ni- and Co-base superalloys. In the other paper, Malte Lenz and colleagues investigate atomic structures and chemical compositions of defects in creep deformed Co-base superalloy and discuss their influence on the mechanical properties.

Congratulations!

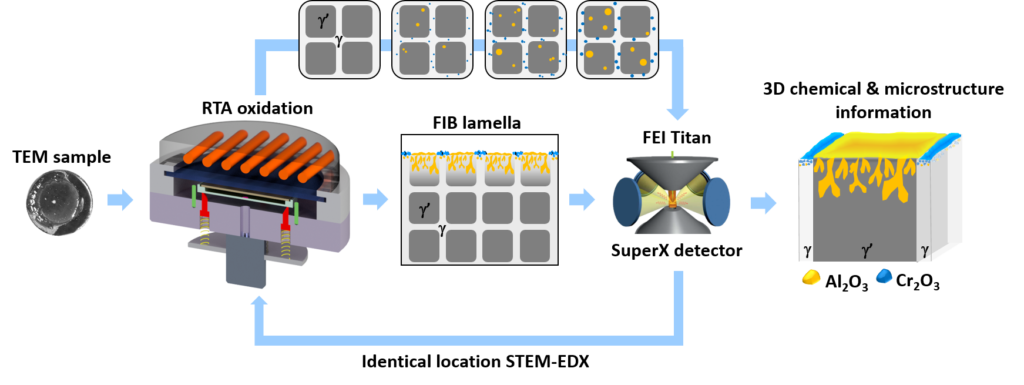

- Using Rapid Thermal Annealing for Studying Early Stages of High-Temperature Oxidation of Superalloys

The great potential of Rapid Thermal Annealing (RTA), a widespread technique in semiconductor technology, for studying high-temperature properties of superalloys is demonstrated. As an application example, early stages of high-temperature oxidation of Co/Ni-base superalloys are investigated. Model alloys with different Co/Ni ratio are oxidized in synthetic dry air at 900 °C to reveal and understand the differences between the oxidation behaviors of Ni- and Co-base alloys. Upon short exposure times (< 64 s), the two-phase γ/γ′ microstructure has a pronounced influence on both the morphology and growth kinetics of Al2O3 precipitates. Depending on the base element, Al2O3 nucleates in either the γ′ phase in the form of needles (Ni-base superalloy) or in the γ matrix as lath- and plate-like precipitates (Co-base superalloy), with the latter showing drastically slower formation kinetics. Observed differences in oxidation behavior can be directly correlated to changes in the partitioning of W, which acts as a γ former in Ni- and a γ′ former in Co-base superalloys. We propose that a significant amount of W in γ′ has an inhibitory effect on the diffusion of Al, suppressing the formation of Al2O3 in the γ′ phase of Co-base superalloys. Our approach proved to be very successful for oxidation studies and opens up new opportunities for superalloys research.

Link to the paper: https://www.springerprofessional.de/using-rapid-thermal-annealing-for-studying-early-stages-of-high-/18327556

- Atomic Structure and Chemical Composition of Planar Fault Structures in Co-Base Superalloys

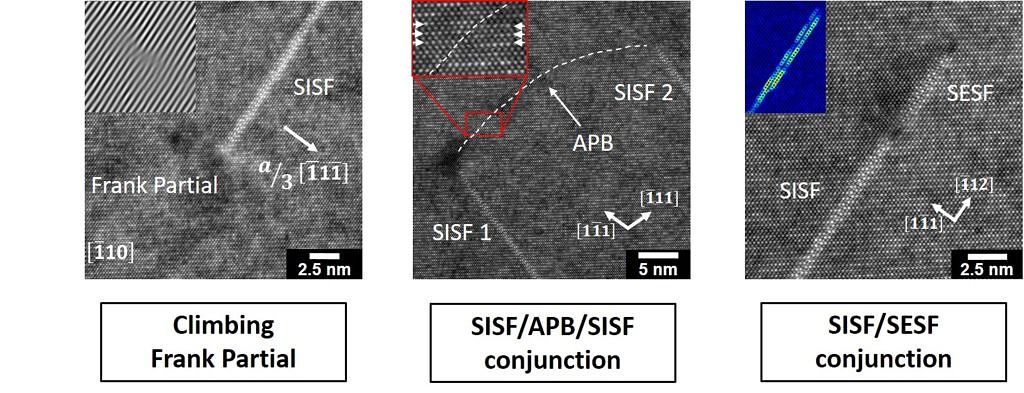

We report on the atomic structure and chemical composition of defects associated with creep deformation of Co-base superalloys and discuss their formation and contribution to plastic deformation. A multinary single crystalline Co-base superalloy was creep deformed under tension along [001]-direction at 850 °C and 400 MPa. The creep microstructure comprises a high density of planar defects. Solute segregation to superlattice intrinsic stacking faults (SISF) is characterized via EDXS analysis of a statistically relevant number of faults and compared at different creep stages. The amount of solute segregation shows negligible difference at different creep stages indicating that segregation directly occurs during planar fault formation and does not significantly evolve afterward. Based on the observation and analysis of Frank partial dislocations with a/3⟨111⟩ Burgers vectors terminating SISF, we discuss a new route to SISF formation via dislocation climb. Additionally, two more complex fault structures are analyzed, and potential formation mechanisms are discussed. The first of these structures is a terminating end of an SISF where an a/3⟨112⟩ partial dislocation splits up into two closely spaced a/6⟨112⟩ partials separated by an SESF. The second structure consists of two parallel SISFs connected by an anti-phase boundary (APB). All deformation mechanisms described in this study show an involvement of solute segregation directly affecting formation and propagation of creep defects by changing planar fault energies and chemical environments of dislocations. Solute segregation is therefore expected to be a key to future alloy design by enabling control of creep deformation mechanisms in specific temperature and stress regimes.

Link to the paper: https://www.springerprofessional.de/atomic-structure-and-chemical-composition-of-planar-fault-struct/18327594

- , , , , , , , :

Atomic Structure and Chemical Composition of Planar Fault Structures in Co-Base Superalloys

14th International Symposium on Superalloys, Superalloys 2021 (Seven Springs, PA, September 12, 2021 - September 16, 2021)

In: Sammy Tin, Mark Hardy, Justin Clews, Jonathan Cormier, Qiang Feng, John Marcin, Chris O'Brien, Akane Suzuki (ed.): Minerals, Metals and Materials Series 2020

DOI: 10.1007/978-3-030-51834-9_90

BibTeX: Download