Landmark work on the study of high temperature diffusion in multi-component superalloys published in Scripta Materialia

Ni-based superalloys exhibit outstanding high-temperature mechanical properties, which makes them uniquely suitable for modern jet engines and power plants. Their superb high-temperature performance (e.g., creep strength, oxidation resistance) are to large parts governed by the elementary processes of diffusion, as increasingly amount of evidences have pointed out in recent years in the superalloy community. Diffusion data can be experimentally measured (mostly from time evolution of transient states in binary diffusion couples) or theoretically calculated. Since diffusion of a specific element in a materials matrix heavily rely on the number coupling elements and chemical environment in the diffusion material (e.g. Re in Ni-base superalloy with 10 alloying elements), diffusion coefficients from binary diffusion couples may significantly deviate from that in multi-component systems; and wrongly treatment of diffusion pathways can end up with orders-of-magnitude error in theoretical calculations.

Now, at the institute of Micro- and Nanostructure Research (IMN), a landmark work on the study of high temperature diffusion in multi-component superalloys has been published by Yolita Eggeler, Dorota Kubacka, Peter Pichler, Mingajin Wu and Erdmann Spiecker under the title “Intrinsic nano-diffusion-couple for studying high temperature diffusion in multi-component superalloys“, has been published in Scripta Materialia. Congratulations to all the authors for this achievement!

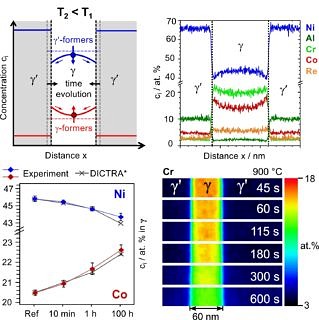

In this work, the authors present a new approach for the quantitative study of high-temperature diffusion in multicomponent superalloys. The approach utilizes the γ/γ’-microstructure itself as intrinsic nano-diffusion-couple. By establishing equilibrium at one temperature followed by annealing at a different temperature, well-defined transient states are generated which are then studied using analytical transmission electron microscopy (TEM). This approach is successfully demonstrated for a high-performance multi-component superalloy of CMSX-4 type. The temporal evolution of element concentrations is consistently revealed for γ- and γ’-forming elements and is compared to multi-component diffusion DICTRA simulations. Excellent agreement is obtained for Ni, Co, and Cr whereas diffusion of Al and, in particular, Re lacks behind in the experiment. Moreover, it is demonstrated that transient states can also be captured by in-situ TEM using chip-based heating devices. The nano-diffusion-couple approach offers great opportunities for diffusion studies in compositionally complex superalloys and might be extended to other two-phase multicomponent systems.

The research work was made possible through financial support by the German Research Foundation (DFG) via the SBF-TR 103 “From atoms to turbine blades – a scientific basis for a new generation of single crystal superalloys”, a collaborative project of research groups from the Friedrich-Alexander-University of Erlangen Nürnberg (FAU) and the Ruhr University Bochum (RUB).

- , , , , :

Intrinsic nano-diffusion-couple for studying high temperature diffusion in multi-component superalloys

In: Scripta Materialia 192 (2021), p. 120-124

ISSN: 1359-6462

DOI: 10.1016/j.scriptamat.2020.10.002

BibTeX: Download