Novel model describing high-temperature oxidation behavior of SX Ni- and Co-base Superalloys

The paper ”Early stages of high-temperature oxidation of Ni- and Co-base model superalloys: A comparative study using rapid thermal annealing and advanced electron microscopy” by Dorota Kubacka, Martin Weisser and Erdmann Spiecker has recently been published in Corrosion Science. Congratulations! In this paper, a novel approach that combines rapid thermal annealing (RTA) and advanced electron microscopy techniques has been successfully developed and applied to investigate the early stages of oxidation of superalloys, and used to explain the differences between oxidation performance of SX Ni- and Co-base Superalloys.

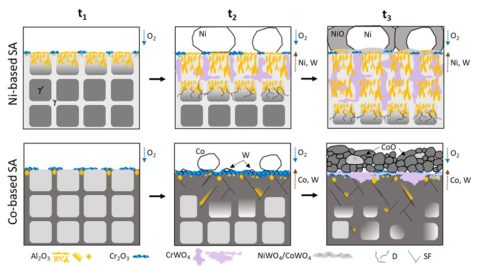

Ni-base single-crystal (SX) superalloys exhibit excellent high-temperature properties owing to their characteristic two-phase γ/γ’ microstructure. However, they are expected to reach fundamental limit soon. Multicomponent γ’-strengthened Co-base SX superalloys may potentially replace their Ni-base counterparts in a certain range of applications. They have proven remarkable mechanical properties, including high creep resistance and fatigue strength. However, poor oxidation resistance of this new class of superalloys at 900 ⁰C and above, resulting from the inability to form a continuous Al2O3 layer, significantly limits the range of possible applications. Though extensive research on the high-temperature oxidation of γ’-strengthened Ni-base SX superalloys in literature, there are clear indications that the oxidation mechanism of γ’-strengthened Co-base SX superalloys significantly differs from that of Ni-base superalloys. However, comparative studies to reveal the key differences in oxidation mechanisms of the two superalloys is challenged by two aspects. First, the microscopic oxidation processes develop rapidly and in a complex way already after few seconds of exposure to oxygen; second, direct comparison is not straightforward due to different compositions of the alloying elements typically added to Ni- and Co superalloys, further complicating the disentanglement of different oxidation mechanisms.

In this study, RTA, an established processing method widely used in semiconductor technology, has been successfully transferred to superalloy research to investigate the early stages of oxidation of Ni- and Co-base superalloys. Thanks to the highly controlled temperature and atmosphere of the RTA furnace the samples can be oxidised for ultra-short times at high temperatures while being well-protected during ramping and cooling, the major limitation of other approaches to study early stages of high temperature oxidation. In fact, using RTA oxidation stages after 2 seconds of exposure at 900 ⁰C could be reliably studied and the microstructural evolution at the oxidation front could be clearly revealed in cross-sectional TEM specimens. To tackle the second challenge, two model SX superalloys with exactly the same addition of alloying elements (Ni-9Al-8W-8Cr and Co-9Al-8W-8Cr) were used to systematically study differences in oxidation behavior between the two classes of superalloys at 900 ⁰C. The obtained STEM-EDX results demonstrated the individual role of the γ and γ’ phase during initial oxidation (2 – 512s). Observed differences in Al2O3 formation could be directly correlated to changes in the partitioning behavior and the type of defects introduced during oxidation, depending on the base element. Explanations for the worse oxidation resistance of γ’-strengthened Co-base superalloys are proposed in the paper.

- , , :

Early stages of high-temperature oxidation of Ni- and Co-base model superalloys: A comparative study using rapid thermal annealing and advanced electron microscopy

In: Corrosion Science 191 (2021), Article No.: 109744

ISSN: 0010-938X

DOI: 10.1016/j.corsci.2021.109744

BibTeX: Download