High-temperature materials

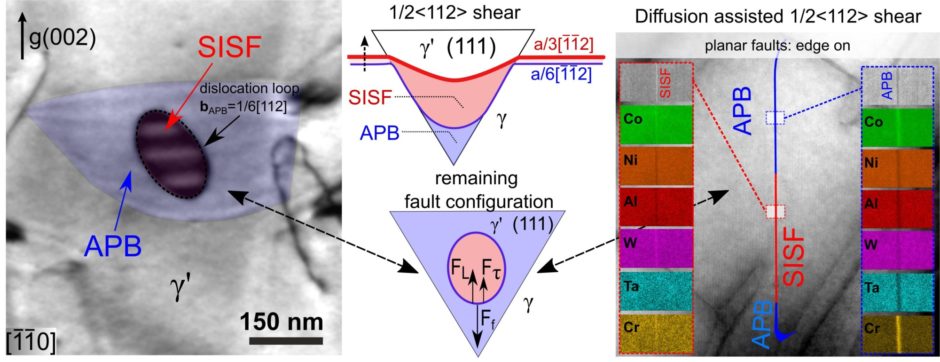

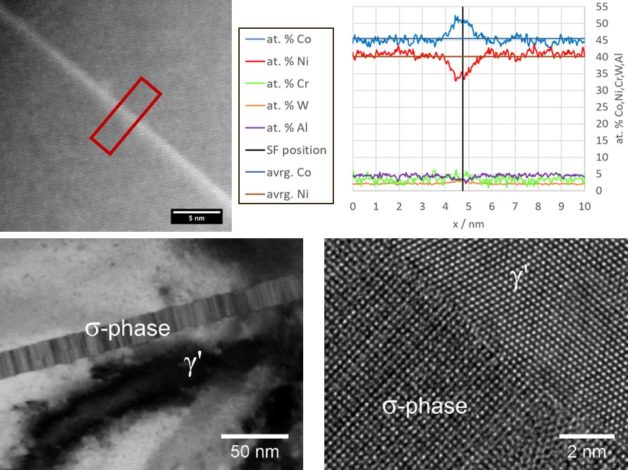

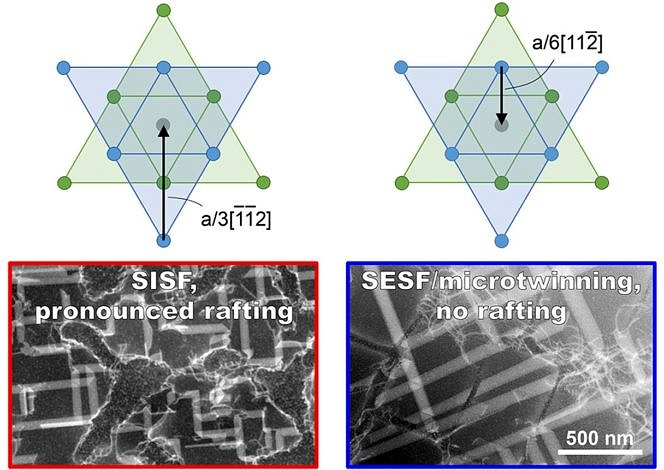

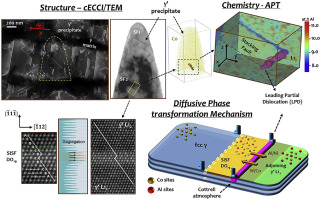

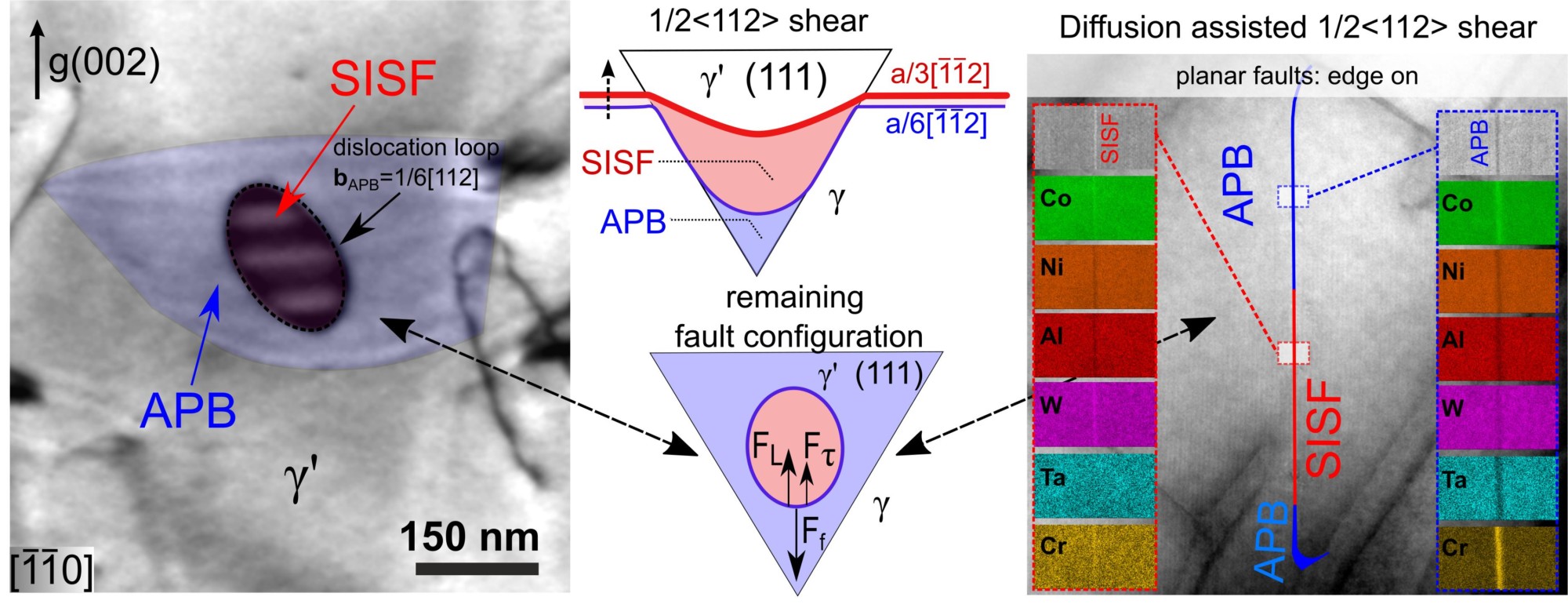

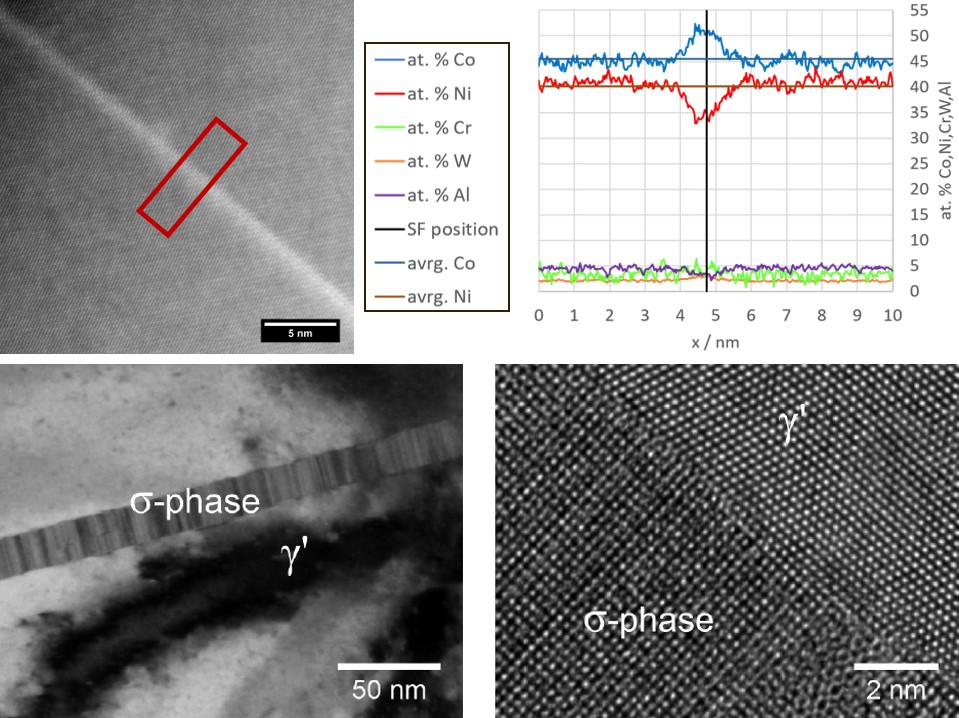

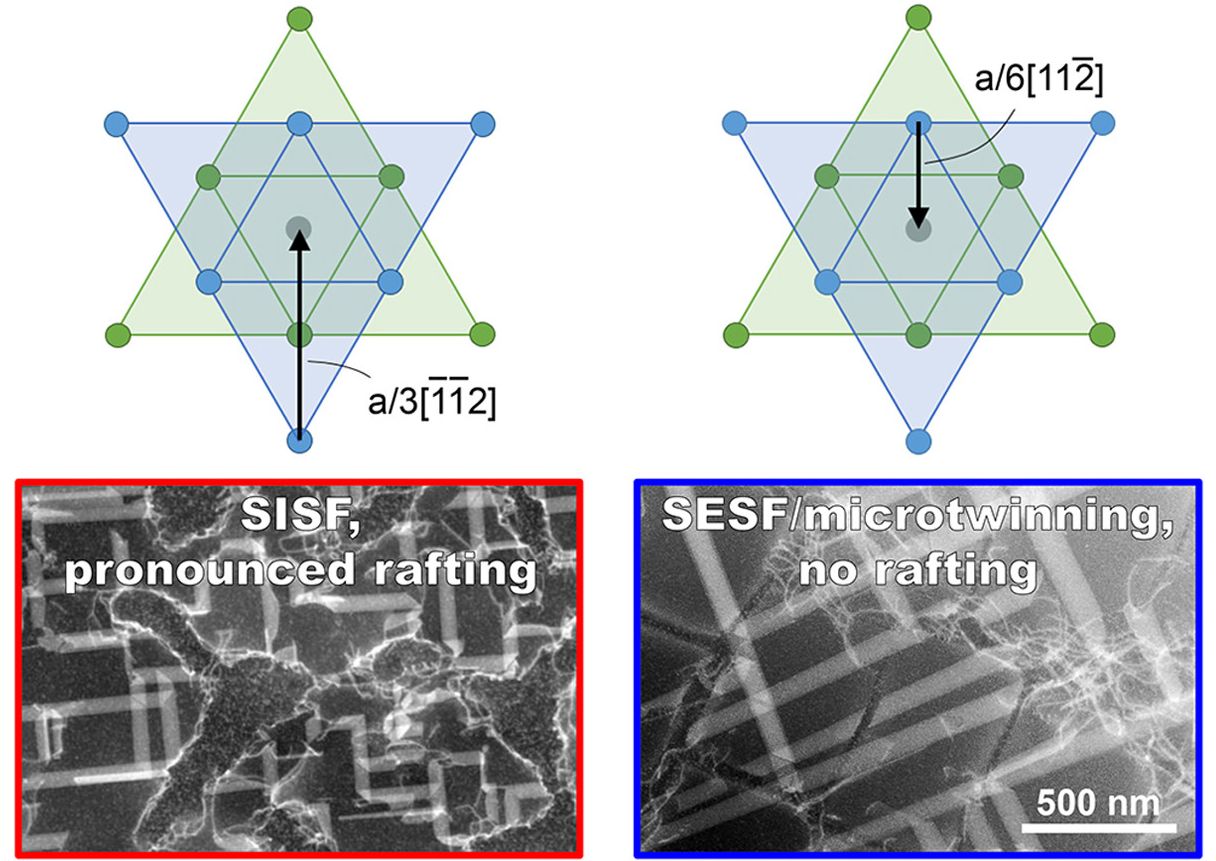

Single-crystalline Nickel based superalloys are the state-of-the-art material system for high-temperature applications in harsh environments and under high loads (e.g., turbine blades in aircraft engines where the material is operating in the creep range at temperatures above 1000⁰C). Since the discovery of a stable L12 phase in the ternary Co-Al-W system by Sato et al. in 2006, the investigation of this new class of high temperature material has substantially expanded. In recent years, the local chemical composition of dislocations and planar defects like, e.g., intrinsic/ extrinsic stacking faults or nanotwins, formed upon high temperature creep in superalloys attracted particular attention. It was shown that solute segregation can either assist plastic deformation by lowering planar fault energies or prevent further growth of defects through local phase transformations. Co-base superalloys are particularly prone to formation of planar faults enabling detailed investigations of segregation phenomena.

This area of research at our institute is funded by the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG) within the long-term project Collaborative Research Center (CRC, German: SFB) Transregio 103 “From atoms to turbine blades – a scientific basis for a new generation of single crystal superalloys”, one of the largest collaborative projects in the field of single crystal superalloy research worldwide, which is now under review to transit to its third funding period. Over the last decade, our institute has made important contributions in fundamental research on superalloys. Encompassing Ni-/Co-base superalloys, we have been developing and applying advanced microscopy methods to tackle scientific challenges in these materials from three main aspect:

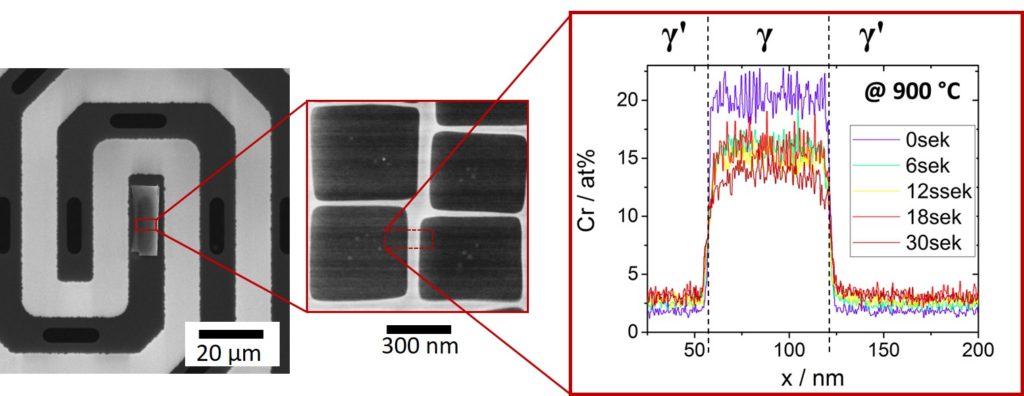

To understand the creep behavior it is important to follow the microstructural and chemical evolution during deformation. We utilize advanced aberration-corrected high resolution and analytical transmission electron microscopy (TEM) as well as convergent beam electron diffraction techniques to study the atomic structure and chemistry of dislocations, planar defects and interfaces with the goal to contribute to an understanding of their role for the creep properties of Ni- and Co-base superalloys.

We explore the capabilities of in-situ chip-based heating systems to gain insight into the temperature dependent γ/γ’ lattice misfit, the formation of tertiary precipitates and TCP phases and the behavior of crystal defects at elevated temperatures.

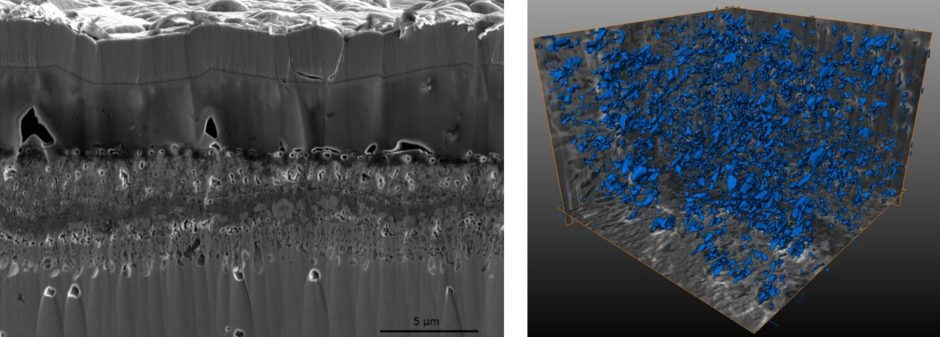

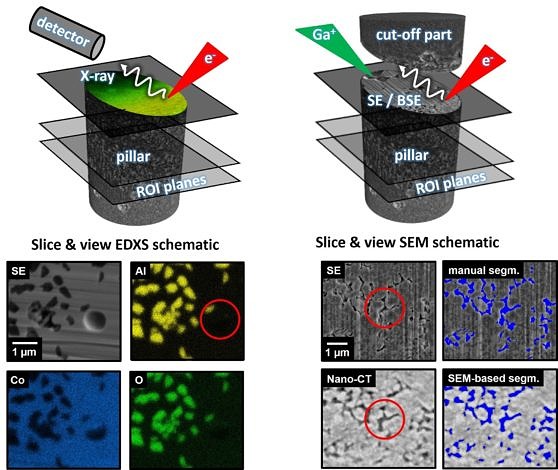

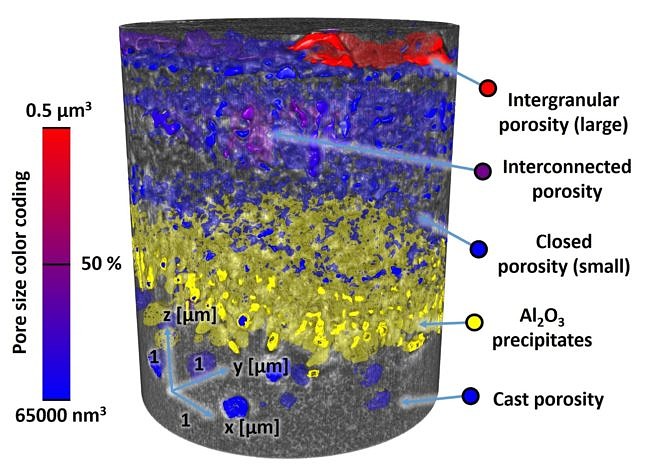

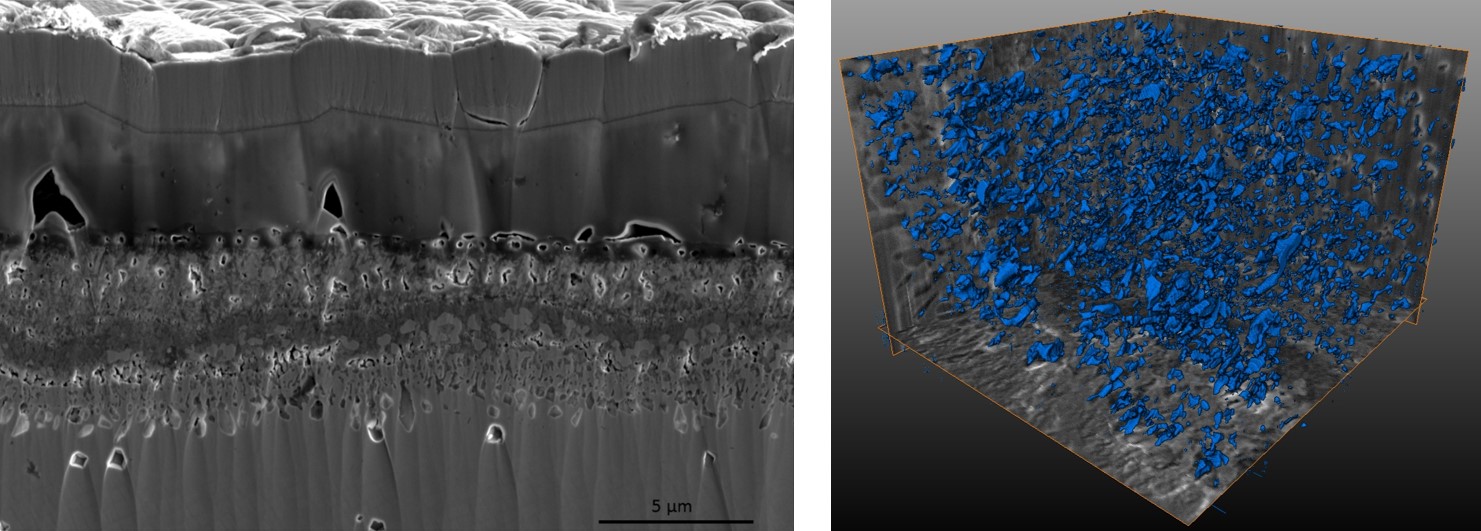

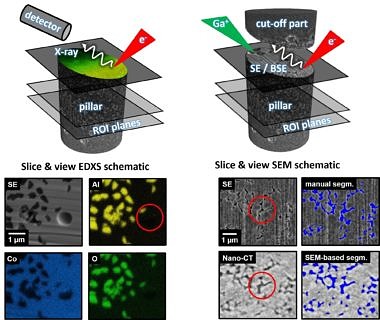

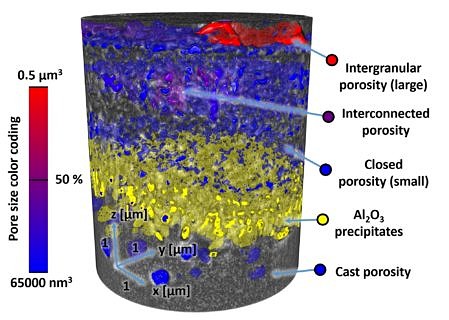

A further focus of our research in the field lies on the 3D characterization of oxide layers of Co- and Ni-based superalloys with FIB-tomography and X-ray tomography to understand the mechanisms behind the formation of phases and pore structures in oxide scales and the degradation of surfaces in general.

Group photo (before COVID)

Current PhD students

Graduated PhDs

Dr.-Ing. Julian Müller

Dr.-Ing. Yolita Eggeler

Dr.-Ing. Malte Lenz

Dr.-Ing. Dorota Kubacka

- , , , , , , , , , :

Tension/Compression asymmetry of a creep deformed single crystal Co-base superalloy

In: Acta Materialia 166 (2019), p. 597-610

ISSN: 1359-6454

DOI: 10.1016/j.actamat.2018.12.053

BibTeX: Download - , , , , , :

Elemental segregation to antiphase boundaries in a crept CoNi-based single crystal superalloy

In: Scripta Materialia (2018), p. 62-66

ISSN: 1359-6462

DOI: 10.1016/j.scriptamat.2018.07.042

BibTeX: Download - , , , , , , , , , , :

Correlative Microscopy-Novel Methods and Their Applications to Explore 3D Chemistry and Structure of Nanoscale Lattice Defects: A Case Study in Superalloys

In: JOM Journal of the Minerals, Metals and Materials Society 70 (2018), p. 1736-1743

ISSN: 1047-4838

DOI: 10.1007/s11837-018-2802-7

BibTeX: Download - , , , :

Early stages of scale formation during oxidation of γ/γ' strengthened single crystal ternary Co-base superalloy at 900 °C

In: Corrosion Science 135 (2018), p. 78-86

ISSN: 0010-938X

DOI: 10.1016/j.corsci.2018.02.020

BibTeX: Download - , , , , , , :

On the nucleation of planar faults during low temperature and high stress creep of single crystal Ni-base superalloys

In: Acta Materialia (2017)

ISSN: 1359-6454

DOI: 10.1016/j.actamat.2017.09.063

BibTeX: Download - , , , , , :

Planar defect formation in the gamma' phase during high temperature creep in single crystal CoNi-base superalloys

In: Acta Materialia 113 (2016), p. 335-349

ISSN: 1359-6454

DOI: 10.1016/j.actamat.2016.03.077

BibTeX: Download - , , , , , , , , , , , , :

Identification of a ternary μ-phase in the Co-Ti-W system – An advanced correlative thin-film and bulk combinatorial materials investigation

In: Acta Materialia 138 (2017), p. 100-110

ISSN: 1359-6454

DOI: 10.1016/j.actamat.2017.07.037

URL: http://www.sciencedirect.com/science/article/pii/S1359645417305980

BibTeX: Download