Published in Acta Materialia: identify the complex or superlattice nature of intrinsic and extrinsic stacking faults in superalloys

The paper “Reliable identification of the complex or superlattice nature of intrinsic and extrinsic stacking faults in the L12 phase by high-resolution imaging” by Nicolas Karpstein, Malte Lenz, Andreas Bezold, Mingjian Wu, Stefan Neumeier, and Erdmann Spiecker has just published in the Journal Acta Materialia. Congratulations to Nico and colleagues!

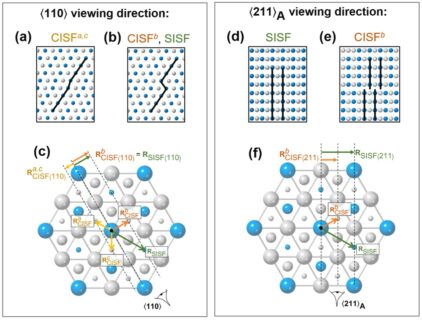

Superalloys are high-performance materials designed for extreme environments. For applications at the highest temperatures in aircraft engines and turbines, they are produced in a single crystalline form, and their microstructure is tailored to optimize their mechanical strength. The microstructure comprises two phases: a face-centered cubic matrix phase called γ, and a precipitate phase named γ′. The latter exhibits superlattice ordering, where the crystal structure (the so-called L12 structure) contains two distinct types of atomic sites occupied by different elements. This additional ordering has a profound impact on how the γ′ phase deforms plastically, involving numerous configurations of partial dislocations and planar faults. Commonly observed types of planar faults include intrinsic and extrinsic stacking faults, which can be readily distinguished e.g. in high-resolution scanning transmission electron microscopy (HRSTEM). However, in the L12 structure, these faults are further classified in variants called complex and superlattice intrinsic/extrinsic stacking faults, whose distinction is often not as straightforward, but just as crucial to fully understand a given deformation mechanism.

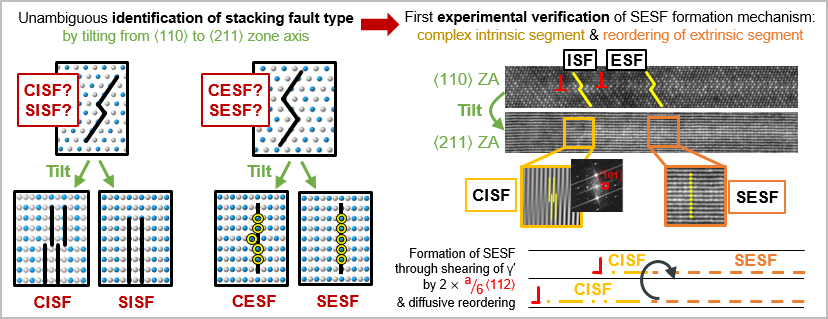

The unambiguous experimental identification of such fault variants in HRSTEM is precisely what our novel characterization method makes possible. In a single HRSTEM image, we only see a 2-D projection of the 3-D fault structure, which may be ambiguous. But by additionally looking at the same stacking fault from a different direction, any ambiguity regarding its structure is resolved, and the necessary sample tilt of 30° is well achievable in the TEM.

Finally, we have applied this new method to examine the so-called Kolbe mechanism, by which superlattice extrinsic stacking faults can form in the γ′ phase. By looking at the leading dislocations that have formed such a fault in the Co-base superalloy ERBOCo-4, we were able to experimentally confirm two aspects of this deformation mechanism: the existence of a complex leading intrinsic segment, as well as the occurrence of a diffusional re-ordering step to transform the complex extrinsic segment into its superlattice counterpart.

We are confident that our new characterization method will also prove worthwhile for the analysis of other γ′ deformation mechanisms in the future, and that it offers an opportunity to expand our knowledge of the mechanical behavior of superalloys at the microscopic scale.

This research work was made possible through financial support by the German Research Foundation (DFG) via the SBF-TR 103 “From atoms to turbine blades – a scientific basis for a new generation of single crystal superalloys”, a collaborative project of research groups from the Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) and the Ruhr University Bochum (RUB).